by Tom Mills

In: The Atlatl 22(2):1-7 (2009)

(Note: This is the tutorial I and many others have learned to make cane, reed or bamboo darts from, and outlines the general method modern atlatlists use, though often with individual variations. Many of the methods also seem to carry over to ancient artifacts. Thanks Tom! ~Devin Pettigrew)

This is a small stand of Arundo donax (an introduced pest in the western United States).

I’m selecting a piece of suitable diameter, and one that is not too green, as I’d like to make a dart almost immediately.

You can find ample amounts of material that is cured sufficiently for immediate use. The top piece is a little too green (although with some curing time – a few months, as it looses moisture slowly – it will be perfect). The second and third pieces from the top are perfect, and ready to be made into darts. The grey patches on the bottom piece tell me that it’s a little to old and dry for an optimal dart. It will work, but it is more likely to break in use.

Tools/materials for making an atlatl dart: Hardwood “dowels” for foreshafts, feathers, artificial or real sinew, a sharp knife with a thin blade, and a pair of scissors.

This is a dry, unstraightened piece of Arundo donax (often referred to as “River Cane”). I cut the raw shafts at approximately 8′-9′ in length. After heat straightening, I will reduce them in size to approximately 7′ in length before making them into darts.

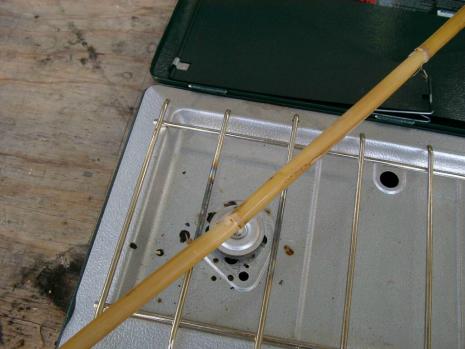

I’ve taken to using a camp stove as a heat source when straightening the cane. You want to avoid over heating the cane. When it’s ready to bend, the outer rind will become glossy with “sweat” as the heat drives the moisture out of the cane. In the photo, you’ll see a bit of a glossy shine right in the area over the heat source. This piece is ready to go..

Although you must primarily heat the problem areas, it’s a good idea to get some heat into the areas adjoining them so that the stress of the bending is spread out a bit. The cane should be kept in constant movement over the flame (both rotational and lateral) to avoid scorching and insure even heating. Bend gently, and go slowly. It’s best to straighten cane in several installments – attack the worst problems first and let the cane cool before further straightening attempts are made. It may take several passes to get the piece straight. Bending the cane over a slightly curved block of wood is a good idea too.

This is the same piece after the first straightening. I’ve found that atlatl dart shafts do not need to be perfectly straight. It seems that as long as the shaft is in line – front to back – a bit of “snakeyness” does little harm. Now it’s time to trim the dart down to its final size. This is important, as the length of the dart will govern the flexibility or “spine” of the dart. I find a good dart is one that begins to flex between 5 – 7 lbs of pressure (see subsequent photos for illustration).

Here’s a shot of the cup on the back of the dart, placed just above, and into one of the nodes. A reinforcing wrap of sinew below the cup is probably a good idea. Select a node that will leave you with a sufficient length of material so that you can adjust the spine of the dart (you can always cut off more, but ya can’t put it back!). Spine can be adjusted in two ways. You can increase the spine weight (make it less flexible) by shortening the dart. Another way to make minor adjustments is to increase or decrease the mass of the fore-shaft (more mass to lighten overall spine – less to increase it), although this method cannot be quantified using the bathroom scale – it must be fine tuned by observing the flight of the dart.

Take the straightened shaft and push it down on a bathroom scale. Note the poundage when the dart just begins to flex. If the cane flexes between 5 – 7 lbs, great. If less than 5lbs, shorten the shaft by trimming from either end (try to keep the nock located on a node, however). If the spine is way over 7lbs, it will usually fly poorly. Once you make a few darts, you’ll get the feel for selecting proper material at the outset. If trying to make a matching set of darts, pay more attention to the spine weight than to the length of the darts themselves. If your dart is spined a bit too heavy, you can adjust it by making a longer, heavier fore-shaft. Again, the bathroom scale test will not be affected by adjustments to the mass of the point – you’ll only see the difference in flight tests.

After the shaft is cut to size, I apply a wrap on the point end in preparation for installing a fore-shaft. Using artificial sinew, I whip-wrap the shaft for about 1″. A whip-wrap requires no knots or glue. While holding the end of a length of sinew it against the shaft (the end of the sinew is under my finger), you wrap the running end over top of it, toward your hand. After only one or two wraps, the sinew will bind upon itself and hold fast. Keep wrapping toward the tail end of the shaft….and then…

…when you’re almost to the end of the sinew, slip a small loop of sinew (a separate piece that you prepared and set aside before starting to wrap) under the running end, and continue to wrap over that as well. In a second or two, you’ll be using that loop to pull the running end back under itself.

Now that you’ve securely wrapped the end of the shaft, it’s time to prepare for insertion of the fore-shaft. Take your sharp knife and ream out the inside of the cane. You want to arrive at a cone shaped interior, with the outer edge almost paper thin. The idea is to weaken the cane so that it will give a bit when we force the fore-shaft inside of it (be patient…you’ll see what I mean. We’ll be making a fore-shaft that will have a taper to it that will mirror the cone-shaped interior of the cane.

Alrighty…the shaft has been prepared to accept a foreshaft. We’ve selected a hardwood branch that is just slightly larger in diameter than the cane, and we’ve begun to carve one end of it to fit inside. The shape of the “spike” on the fore-shaft will match the cone shape of the interior of the main-shaft. You want a really tight fit, so once you get close, go slow and test the fit frequently.

Carve the spike until it almost fits inside, but not quite. When it’s just about perfect, we’ll drive the fore-shaft in by literally slamming it against the ground. The weakened cane will want to give, but the sinew wrap will hold it tight. This friction joint is amazingly strong…you’ll see.

Here’s a shot showing a perfect fit. The fore-shaft is about 1/4″ from its final position. For the moment, it’s in as far as it will go using the pressure of my hands to push it in. The alignment looks good, and it’s time to drive it in that last little bit by slamming it against a hard surface.

Whammo! I’ve driven the fore-shaft the last 1/4″ by slamming it with authority against the bricks. The weakened cane gives just enough to allow the fore-shaft to move in that last bit, but the wrap keeps the main-shaft from splitting. The diameter of the fore-shaft is bigger than the cane, so it simply cannot be driven any further inside.

Time to make the fore-shaft look pointy, sharp and dangerous!

I’ve removed the fore-shaft by wiggling it back and forth a bit and carved it into a proper point. I left a bit of the bark on the fore-shaft to identify the thickest part. Again, the fore-shaft diameter is greater than the main shaft, and this prevents it from ever being forced inside to split the shaft.

Here’s the finished fore-shaft, showing a nice smooth transition from fore-shaft to main-shaft. As I often throw at hay bales, I’ve taken to gluing the foreshafts in with hot-melt glue. When the point needs replacement, the hot-melt glue allows me to easily retract the broken fore-shaft. The over all length of the finished dart is 89″ (81 1/2″ shaft – 7 1/2″ fore-shaft).

This is a different dart than the one we’ve been making, but this photo is evidence of the strength of the fore-shaft attachment. The friction joint withstood a full-force, direct hit on this tree with flying colors.

There are many ways of putting feathers on a dart. I tie them on; here’s how: I cut three feathers (full length turkey feathers) to approximately 6″ in length. I then cut away about 1/4″ of the feather on the front, and the same on the back. I then fold the back over on itself, as in the photo.

After preparing the feathers, I begin a whip wrap with a length of sinew, starting approximately 5″ from the end of the dart (if the feathers are too close to the nock, they interfere when nocking the dart on the thrower). After a few turns around the shaft, insert the bent end of the rear of the feather under the wrap and pin it to the shaft. You’ll feel like you need another set of hands to do this. Holding the sinew in your teeth will allow you two hands free for the operation. I rotate the shaft at this point, rather than winding the sinew around it. Add the 2nd and 3rd feather as you go, spacing them as evenly as possible around the shaft.

Keep wrapping down the shaft after the 3rd feather is attached, and repeat the steps to finish off the whip-wrap (e.g., laying down a loop of sinew, wrap over it, then pull the end back under…see earlier photos). These feathers have a nice even spacing.

Now the fun part! Pull the feathers forward, as tightly as possible against the shaft. Mark the point where the front of the feather lands, and let the feather spring back up out of the way. Then start another whip-wrap at the point you marked. Take a few turns around the shaft until the sinew binds upon itself. Holding the sinew in your teeth, pull down the first feather (as snugly as possible against the shaft) and pin it down by wrapping the sinew over it. I find it easiest to make a turn or two around the shaft and feather before moving on to the next feather. To pin them down as tightly as possible, it helps to press down the bent part on the back of the feather while you pull the feather with your other hand.

Do the same with all three feathers, continue the whip-wrap for a short distance and finish it off as before. You’ll see that due to irregularities in the shaft material, the feathers don’t lay completely flat (this is the primary reason why I tie them instead of gluing). Don’t worry…we’re going to fix that by making one last wrap with sinew – this one, spiraling up and through the feathers from front to back.

For the final feather wrap, you’ll start in the front and work toward the tail end of the dart. Start another whip-wrap in the front of the feathers, and then holding the dart at a slight angle, pass the sinew through the feathers one at a time. In the end, it will look like stripes on a candy cane. This part is a little bit tricky and takes some practice. You’ll find it helpful to make way for the sinew by spreading the feathers with your fingers (see photo). When you get to the end of the feathers, continue wrapping for a bit, and finish off the whip-wrap as we did earlier. You can then trim the feathers to any shape you desire, or leave them as is. Shortening them some will make for a faster/further flying dart.

Voila! A compete dart. The fletching method may seem overly involved and difficult to do. With a little practice, however, you’ll find that it’s pretty easy to do and you’ll make quick work of it. Lots of folks start wrapping in the front of the feather, and continue through the feather to the rear. I’ve come to be comfortable doing it this way. In the end, it probably doesn’t matter very much – whatever works best for you!